IoT for Real-Time Tracking in Logistics

Imagine a logistics manager in New York tracking a shipment traveling across the country. A minor delay or misplacement could disrupt the entire supply chain. In the fast-paced world of logistics, traditional tracking methods often fall short, causing inefficiencies and uncertainties. Enter IoT—an innovation transforming real-time shipment and asset tracking, ensuring accuracy and transparency from start to finish.

The Rise of IoT in Logistics

The Internet of Things (IoT) connects everyday objects through sensors and networks, enabling them to send and receive data. For logistics, this translates to smarter, connected supply chains. By 2025, it’s estimated that the global IoT in logistics market will reach $63.7 billion, growing at a CAGR of 13.2% from 2020 to 2025.

How IoT Enhances Real-Time Tracking

1. Smart Sensors and Trackers

IoT sensors attach to shipments, vehicles, or warehouse assets, providing real-time updates on:

- Location: GPS-enabled trackers offer accurate positioning.

- Temperature: Ensuring perishable goods stay within safe limits.

- Condition Monitoring: Vibration or tilt sensors detect mishandling or damage.

Example:

A pharmaceutical company transporting vaccines can use IoT sensors to monitor temperature-sensitive shipments. Any deviation triggers an alert, allowing immediate corrective action.

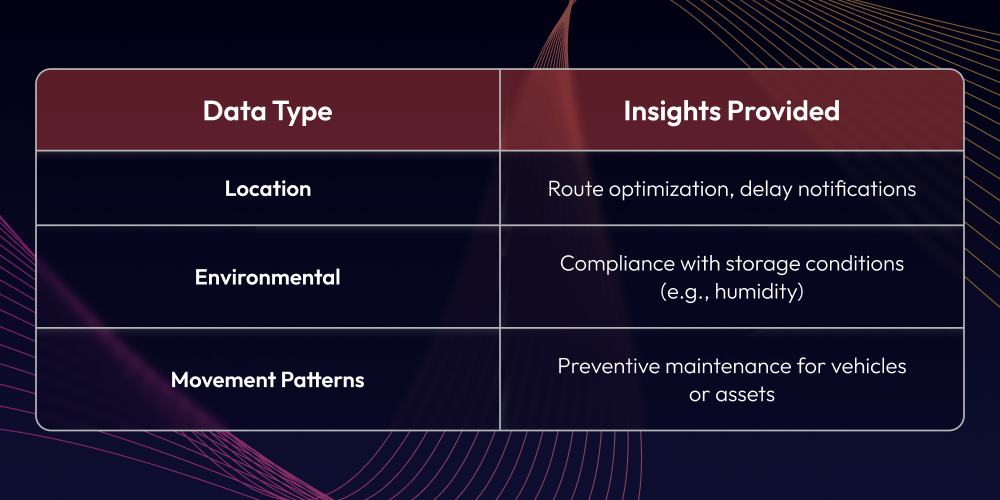

2. Real-Time Data Transmission

IoT devices transmit data via cellular, Wi-Fi, or satellite networks. This continuous data stream ensures stakeholders have up-to-date information. Advanced platforms aggregate and analyze this data, presenting insights through dashboards.

Key Benefits of IoT in Logistics

1. Enhanced Visibility and Transparency

IoT provides end-to-end visibility across the supply chain. Real-time updates reduce uncertainty, helping companies manage expectations and communicate better with customers.

Stat: 89% of logistics companies believe that visibility is a key competitive advantage.

2. Improved Asset Utilization

IoT-enabled tracking prevents asset underutilization by providing real-time insights into fleet and equipment usage. This data helps optimize resource allocation, reducing costs.

3. Reduced Losses and Delays

Cargo theft and shipment misplacement are major concerns. IoT-enabled tracking systems reduce these risks by providing real-time alerts and geofencing capabilities.

Story: A logistics provider transporting electronics reduced cargo theft incidents by 30% using IoT tracking and geofencing solutions. Alerts notified operators if a shipment deviated from its predefined route, enabling quick responses.

Process of Implementing IoT in Logistics

Step 1: Identifying Objectives

Determine specific goals:

- Improving shipment visibility?

- Enhancing warehouse efficiency?

- Reducing operational costs?

Step 2: Choosing IoT Devices

Select suitable devices based on cargo and environmental conditions:

- GPS trackers for vehicles.

- RFID tags for inventory.

- Temperature sensors for perishables.

Step 3: Integrating IoT Platforms

Choose a cloud-based platform to aggregate data from multiple sources. Platforms with AI and analytics capabilities provide actionable insights.

Step 4: Data Analysis and Actionable Insights

Utilize collected data to optimize routes, prevent delays, and enhance overall efficiency. Integration with ERP systems can streamline operations.

Challenges and Solutions

1. Data Security Concerns

IoT networks are vulnerable to cyberattacks. Encrypting data and using secure cloud services mitigate risks.

2. High Initial Costs

While IoT implementation can be expensive, the long-term ROI is significant. Companies can start with pilot projects to measure impact before scaling.

3. Data Overload

Handling vast amounts of data can be challenging. Implementing AI-driven analytics helps filter valuable insights from raw data.

Future of IoT in Logistics

The future of IoT in logistics is promising, with advancements in:

- 5G Technology: Faster data transmission.

- AI Integration: Predictive analytics for proactive decision-making.

- Blockchain: Enhanced transparency and security.

Projection: By 2030, over 70% of supply chain operations are expected to adopt IoT-driven processes

Related Article: Ways IoT Can Enhance The Business Operations In Logistics

Conclusion

IoT offers the key to overcoming traditional challenges, enhancing real-time tracking, and driving efficiency in a dynamic logistics landscape. For logistics companies in the US, adopting IoT isn’t just about staying competitive—it’s about leading the way in supply chain innovation.

Embrace IoT today to build a smarter, connected tomorrow.

Discover how IoT solutions can transform your logistics operations.

Contact Technostacks to explore custom IoT integrations for your supply chain needs.

FAQs

1. What is IoT real-time tracking in logistics?

IoT real-time tracking involves using IoT sensors and devices to monitor the location, condition, and status of shipments, vehicles, and assets in the supply chain. It provides continuous data updates, ensuring accuracy and transparency throughout the logistics process.

2. How does IoT improve efficiency in logistics operations?

IoT enhances logistics efficiency by providing real-time data on shipment status, route optimization, and asset utilization. This helps reduce delays, prevent losses, and improve decision-making, ultimately streamlining operations and cutting costs.

3. What are the key benefits of IoT for supply chain visibility?

IoT offers end-to-end visibility, real-time tracking, and data-driven insights. This reduces uncertainty, improves communication with stakeholders, and enhances customer satisfaction by providing accurate shipment information.

4. How can IoT reduce cargo theft and shipment losses?

IoT-enabled tracking systems use GPS and geofencing to monitor shipments. Any deviation from predefined routes triggers alerts, allowing operators to respond quickly and prevent cargo theft or misplacement.

5. What types of IoT devices are used in logistics tracking?

Common IoT devices include GPS trackers for vehicles, RFID tags for inventory, and temperature or vibration sensors for monitoring perishable or sensitive goods. These devices ensure comprehensive tracking and condition monitoring.

6. What challenges do companies face when implementing IoT in logistics?

Key challenges include data security risks, high initial costs, and managing large volumes of data. Solutions involve using encrypted networks, starting with pilot projects, and leveraging AI-driven analytics to extract actionable insights.

7. How can IoT enhance cold chain logistics for temperature-sensitive goods?

IoT sensors monitor temperature and humidity levels during transit. If any deviations occur, alerts are sent in real-time, allowing logistics managers to take corrective actions to ensure the integrity of temperature-sensitive shipments like vaccines or perishables.

8. What is the future of IoT in the US logistics industry?

The future of IoT in logistics includes advancements in 5G for faster data transmission, AI for predictive analytics, and blockchain for enhanced transparency. By 2030, over 70% of supply chain operations are expected to adopt IoT-driven processes in the US.