Jump to Section

3 Min Read time

Quick Snapshot

A leading tools and equipment retailer struggled with erratic inventory cycles due to demand unpredictability. By deploying advanced forecasting models, such as Random Forest and XGBoost—trained on weekly sales trends—we helped them automate predictions, reduce overstocking, and improve revenue retention.

Brief

Inventory is capital in boxes—too little, and you lose sales; too much, and margins bleed. Northern Tools faced the classic challenge: predicting demand across hundreds of SKUs with variable sales patterns and limited inventory data. Sales anomalies, seasonal swings, and product diversity made manual planning unreliable and time-consuming.

The result?

Smoother stock levels, fewer backorders, and higher revenue retention lower costs.

To cut through this complexity, Technostacks implemented an AI-powered forecasting engine that decoded past trends and predicted future sales with unmatched accuracy.

Challenges

Limited Inventory Visibility

Only aggregate stock data was available—no granular, time-stamped movement at SKU level—making it hard to track true availability or identify stockout-driven dips in demand.

Lack of Real-Time Demand Signals

The retailer relied heavily on weekly sales snapshots, which couldn’t capture demand surges during promotions or weather-driven events. This lag between market activity and system awareness led to missed opportunities and reactive stocking.

Complex, Non-Linear Demand

Seasonality and erratic spikes made standard time-series methods unreliable. Each SKU needed customized windows and decomposition logic.

High Product Variability

Diverse sales behaviors across SKUs meant a single-model strategy fell flat—requiring a modular, product-specific approach.

Solution

We built a robust forecasting pipeline by combining time-series modeling with tree-based machine learning, tailored to each product’s behavior.

Feature

Engineering

Introduced lag-based variables, rolling stats, and seasonality markers to capture short-term spikes and long-term patterns.

Model

Training

Evaluated and optimized multiple ML models (Random Forest, XGBoost, and LightGBM) to benchmark predictive performance.

Advanced

Validation

Used MAE, RMSE, and R² scoring to track model accuracy, while ranking feature importance to refine forecasting logic.

Deployment at

Scale

Integrated forecasting outputs to support real-time inventory decisions—ready for peak sales, flash promos, or quiet seasons.

Impact

RMSE (Root Mean Square Error) measures how close your model’s predictions are to actual outcomes.

Lower RMSE = Higher Accuracy. These results reflect measurable, data-backed gains in forecasting precision.

Ready to make your inventory decisions less reactive and more predictive?

See how AI can move your planning from the warehouse whiteboard to real-time, revenue-driven intelligence.

Our Solutions in Action

Read how we have transformed businesses along the way.

-

How a Chemical Manufacturing Giant Cut Costs by 60% and Accelerated ERP Deployment with Technostacks Zoho Implementation

Growth doesn’t have to wait. With Technostacks certified Zoho expertise, a global chemical leader turned years of ERP setbacks into measurable wins: faster deployment, lower costs, and AI-…

-

Reduce Order Errors. Cut Manual Work. Serve More Customers Without Lifting a Finger

Reduce human intervention in restaurant bookings by 90%, while giving every caller a smooth, intelligent ordering experience without hiring another soul.

-

Automated Answers, Zero Wait Time – Reducing HR Load with a RAG-Based Fleet Chatbot

Turn hours of repetitive HR and ops support into a single chatbot, one that knows every fleet policy, SOP, and HR guideline your team could ask for. It works 24/7, never gets tired, and unde…

-

Modernizing Balikbayan – Automating Last-Mile Delivery for Faster, Smarter Shipping

Sending a Balikbayan box from Sydney to Manila can be seamless, tracked from the moment it’s picked up at your doorstep to the second it reaches your loved one’s hands, all without the h…

-

Driving Performance, Resilience, and $1M Annual Savings Through Strategic Database Modernization

Improving system performance by 23%, cutting downtime incidents by 80%, and saving nearly $1 million annually, all while future-proofing critical infrastructure for a multi-business global e…

-

Executive hiring, reimagined: 90% faster CV reviews, zero compliance errors

Parsing resumes, aligning stakeholder input, and generating compliant, role-specific documents, all done faster than your next coffee break.

-

From 3 Minutes to 30 Seconds: How AI Rewired Plaque Detection for a Leading U.S. Cardiovascular Lab

Convert raw ultrasound scans into quantified arterial insights—automatically, accurately, and in under a minute. No fatigue. No backlog. No bottlenecks.

-

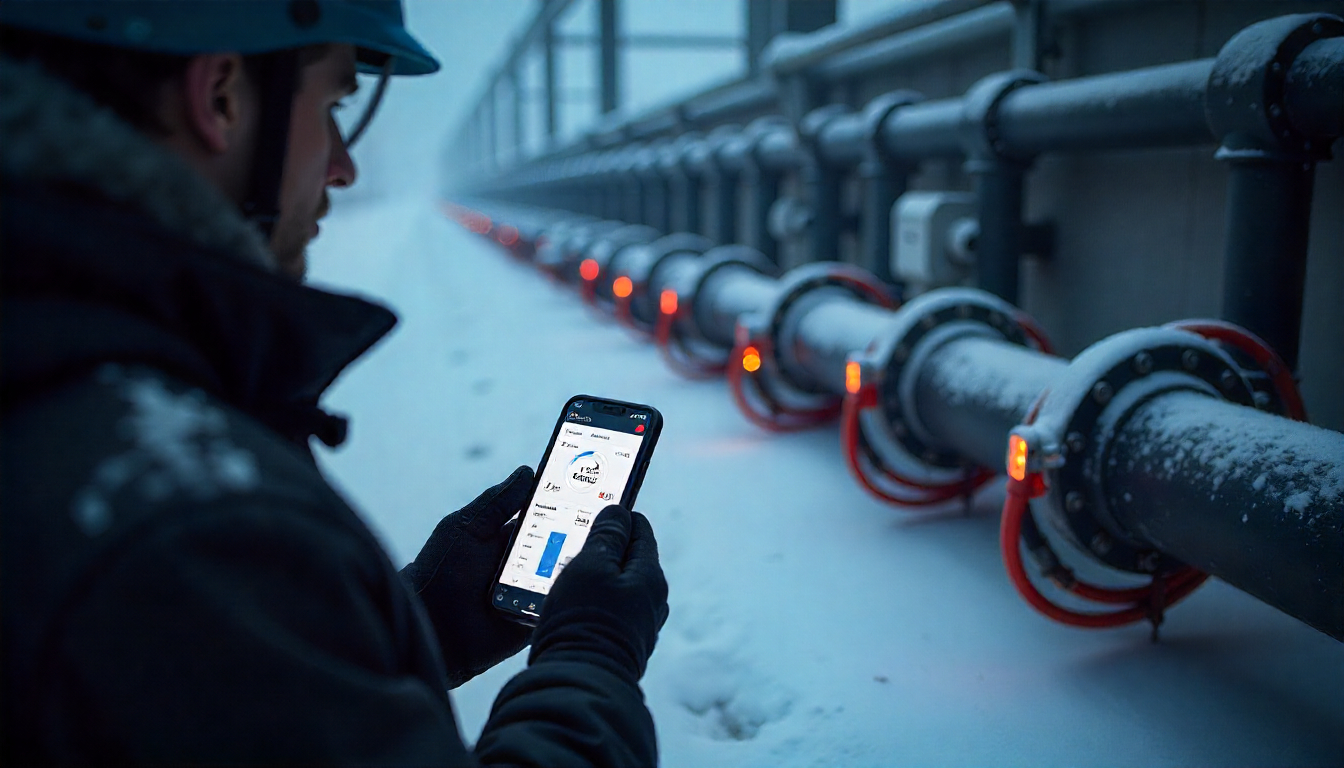

Digitizing Frost Protection – BLE-Powered, Mobile-First, Error-Proof

Configuring and managing heating cables across sub-zero zones without ever touching a control panel. That’s what we delivered: a fully connected, mobile-powered frost protection system tha…

-

Slash turnaround time – Boost ROI and maximize existing resources

Imagine cutting your lab’s turnaround time by 60%, freeing up analysts to focus on high-value work that drives measurable ROI-all without adding headcount.

Lets Talk

Have a challenge?Let us know.