- Lengthy Training Process: Extended onboarding and training time for workers.

- Error-Prone Part Selection: Manual processes led to incorrect part usage.

- Global Consistency: Ensuring similar solutions could be adapted for their US branch.

Brief

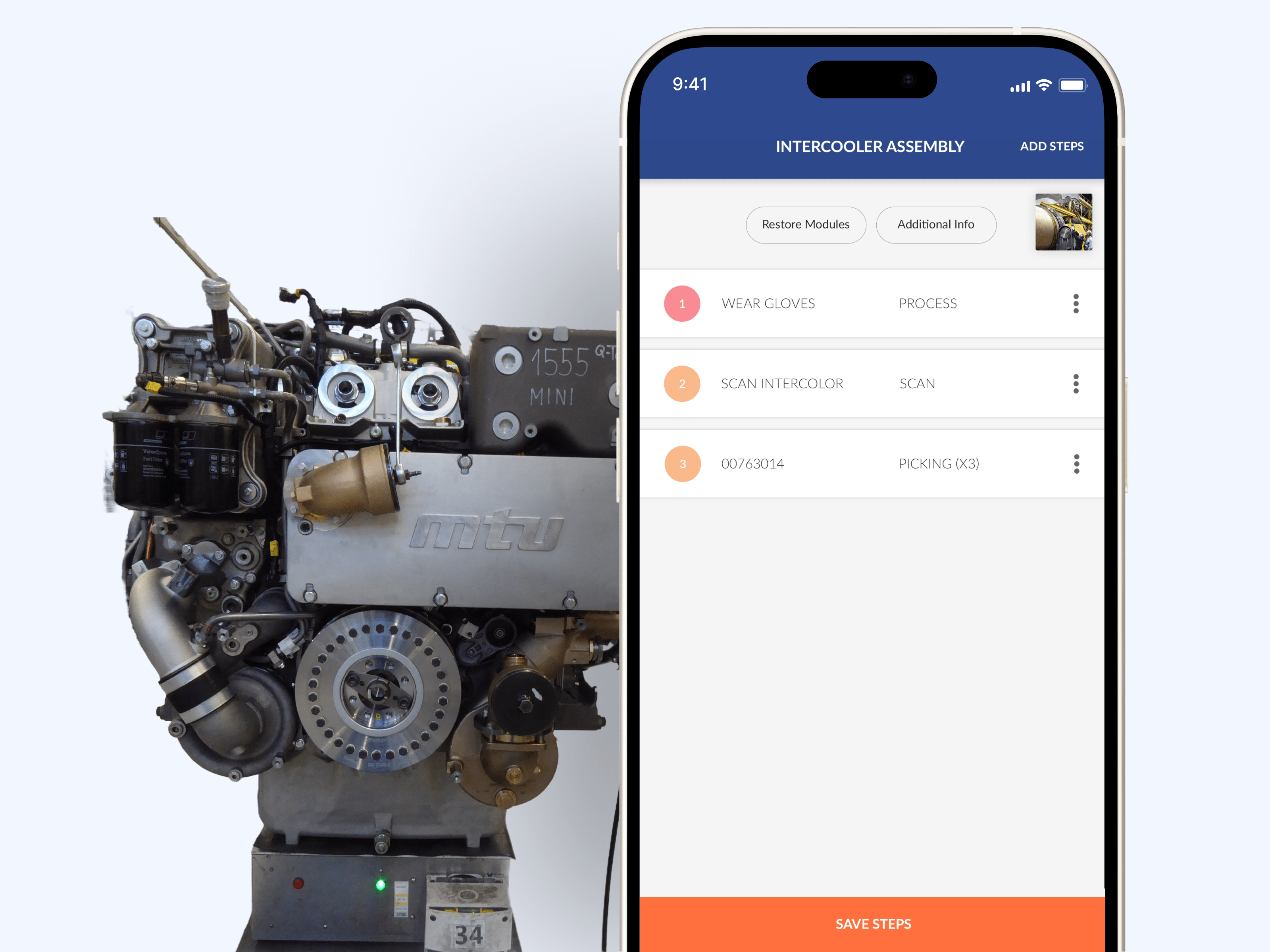

MTU sought to enhance their assembly line processes by reducing training times and minimizing errors. Technostacks collaborated with MTU to design and implement a digital solution involving real-time monitoring tools and computer vision technology.

Challenges

- Training Efficiency: Reducing lengthy training durations without compromising quality.

- Part Accuracy: Ensuring correct parts are picked to avoid assembly errors.

- Real-Time Insights: Providing workers with live feedback on part usage.

- Global Deployment: Scaling solutions for use across multiple international locations.

Solution

Technostacks developed and deployed a suite of digital tools, including:

- Wearable Glove Scanner: A custom-built glove scanner with Bluetooth enabled seamless tracking of assembly parts as per the defined process.

- Google Glasses Integration: Provided real-time insights into equipment and part usage.

- Training Software: A digital product to monitor and assess assembly line performance, reducing training time.

- Computer Vision Technology: Implemented similar solutions for MTU’s US branch to ensure consistency and efficiency.

Impact

- Reduced Training Time: Faster onboarding and improved worker productivity.

- Error Minimization: Accurate part selection and fewer assembly errors resulting in 17% improved efficiency.

- Real-Time Insights: Enhanced operational visibility and decision-making.

- Global Scalability: Solutions adapted successfully for international operations.

86.6%

Client Retention Rate

200+

Delivered Assets

6.4X

ROI of Re-Design

Our Solutions in Action

Read how we have transformed businesses along the way.

-

Industrial • Internet of Things (IoT): Enabling Smarter Industrial, Agricultural & Solar Operations through Long-Range, Low-Power IoT Monitoring with LoRa® Technology

Enabling Smarter Industrial, Agricultural & Solar Operations through Long-Range, Low-Power IoT Monitoring with LoRa® Technology

From noisy factories to sprawling farmlands and solar fields, reliable real-time monitoring was once a distant dream. Traditional wired and Wi-Fi systems failed to cover vast areas or withst…

-

Industrial • Data & AI: How a Jewellery Technology Pioneer Achieved 99% Accurate Diamond Testing with Technostacks AI-Powered Screening App

How a Jewellery Technology Pioneer Achieved 99% Accurate Diamond Testing with Technostacks AI-Powered Screening App

Clarity isn’t just for diamonds. With Technostacks AI-enabled mobile app, a jewellery technology innovator transformed diamond screening into a faster, more accurate, and fully automated e…

-

Industrial • Digital Products • Generative AI: How a Chemical Manufacturing Giant Cut Costs by 60% and Accelerated ERP Deployment with Technostacks Zoho Implementation

How a Chemical Manufacturing Giant Cut Costs by 60% and Accelerated ERP Deployment with Technostacks Zoho Implementation

Growth doesn’t have to wait. With Technostacks certified Zoho expertise, a global chemical leader turned years of ERP setbacks into measurable wins: faster deployment, lower costs, and AI-…

-

Generative AI • Strategic Consulting: Reduce Order Errors. Cut Manual Work. Serve More Customers Without Lifting a Finger

Reduce Order Errors. Cut Manual Work. Serve More Customers Without Lifting a Finger

Reduce human intervention in restaurant bookings by 90%, while giving every caller a smooth, intelligent ordering experience without hiring another soul.

-

Logistics • Cloud & DevOps • Generative AI • Strategic Consulting: Automated Answers, Zero Wait Time – Reducing HR Load with a RAG-Based Fleet Chatbot

Automated Answers, Zero Wait Time – Reducing HR Load with a RAG-Based Fleet Chatbot

Turn hours of repetitive HR and ops support into a single chatbot, one that knows every fleet policy, SOP, and HR guideline your team could ask for. It works 24/7, never gets tired, and unde…

-

Logistics • Data & AI • Digital Products • Strategic Consulting: Modernizing Balikbayan – Automating Last-Mile Delivery for Faster, Smarter Shipping

Modernizing Balikbayan – Automating Last-Mile Delivery for Faster, Smarter Shipping

Sending a Balikbayan box from Sydney to Manila can be seamless, tracked from the moment it’s picked up at your doorstep to the second it reaches your loved one’s hands, all without the h…

-

Cloud & DevOps • Data & AI: Driving Performance, Resilience, and $1M Annual Savings Through Strategic Database Modernization

Driving Performance, Resilience, and $1M Annual Savings Through Strategic Database Modernization

Improving system performance by 23%, cutting downtime incidents by 80%, and saving nearly $1 million annually, all while future-proofing critical infrastructure for a multi-business global e…

-

Cloud & DevOps • Data & AI • Generative AI: Executive hiring, reimagined: 90% faster CV reviews, zero compliance errors

Executive hiring, reimagined: 90% faster CV reviews, zero compliance errors

Parsing resumes, aligning stakeholder input, and generating compliant, role-specific documents, all done faster than your next coffee break.

-

Healthcare • Data & AI • Digital Products • Strategic Consulting: From 3 Minutes to 30 Seconds: How AI Rewired Plaque Detection for a Leading U.S. Cardiovascular Lab

From 3 Minutes to 30 Seconds: How AI Rewired Plaque Detection for a Leading U.S. Cardiovascular Lab

Convert raw ultrasound scans into quantified arterial insights—automatically, accurately, and in under a minute. No fatigue. No backlog. No bottlenecks.

Lets Talk

Have a challenge?Let us know.